India is well known for its tradition and so is its tradition of storing water with earthenware. It’s an age-old concept that has deserted with time. Pottery in the Indian subcontinent has an ancient history and is one of the most tangible and iconic elements Of Indian art. Evidence of pottery has been found in the early settlements of Lahuradewa and later the Indus valley civilization Today, it is a cultural art that is still practiced extensively in the Indian subcontinent Until recent times all Indian pottery has been Earthenware.

When gods and demons were churning the ocean (Sheersagar) for the divine Nectar (Mahamrita), an earthen pot emerged. This is believed to be the first earthen pot ever created by the potters.

Commonly known as Matkas, earthen pots are a vital accessory for Indian kitchens. They function as traditional refrigerators. The porous nature of these pots makes the accommodated water sift through the pores. The sifted water extracts heat from the water contained in the pot and evaporates from the surface. It’s a continuous process, which keeps the surface of the pot moist and keeps the water temperature low. The more is the ambient heat, the more will be the cooling effect. This golden concept was then washed over by modernization as we moved to the stainless steel or bone china or melamine era.

One can get a rare antique of an earthen pot in a few homes these days, the reason being its natural benefits. Earthenware has tremendous health benefits. The porous material of clay helps water seep through it, letting you enjoy the mildly cool water. Not only this but the mineral composition and porous nature of clay pots and other clay products are also beneficial for the food items stored in it.

The process starts with the soft clay being shaped on a potter’s wheel, after attaining the desired cylinder-like shape, the molded piece is separated at the base with the help of a thread. This shape is then put to dry to gain some rigidity. The pot is again cleaned and formed with a shaping pad and a wooden beater. To give a uniform wall thickness to the pot and impart a fine spherical shape, the potter presses the shaping pad on the inside of the pot and beats the outer surface continuously with the wooden beater. Afterward, these pots are cleaned and checked for any defects. The earthenware fired in an open kiln on the ground has an auburn or brownish-red appearance and the pieces fired in an underground or closed kiln are black in color.

But in recent times we see that there is a problem of Storage of fruits/vegetables/milk etc. in rural areas/remote areas in homes. Villagers who are poor can’t afford a refrigerator. Also, Nomads who travel to different places do not have proper facilities to store their food products. During the summer season, Fruits and vegetables get spoiled. Also, they do not remain fresh till evening. Milk gets spoiled and their food items also get destroyed due to high temperatures.

Also, the fruit and vegetable vendors who sell in wooden carts (the last) face the problem that the vegetables and fruits do not remain as fresh as morning.

As a result, people do not buy them as it does not remain fresh. Thus vendors instead of keeping them, sell them at a very low cost so that it does not become a burden to him as the next day he has to buy fresh items to cater needs of people.

Pottery And It’s Importance

Pottery plays an important role in studying culture and reconstructing the past. Historically with distinct cultures, the style of pottery changed. It reflects the social, economic, and environmental conditions in a culture that thrived in, which helps the archaeologists and historians in understanding our past. Pottery is the process and the product of forming vessels and other objects with clay and other ceramic materials, which are fired at high temperatures to give them a hard, durable form.

Major types include earthenware, stoneware, and porcelain. The place where such wares are made by a potter is also called pottery (plural “potteries”). The definition of pottery used by the American Society for Testing and Materials (ASTM), is “all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products. In archaeology, especially of ancient and prehistoric periods, “pottery” often means vessels only, and figures of the same material are called “terracottas.”

Clay as a part of the materials used is required by some definitions of pottery, but this is dubious. Pottery is one of the oldest human inventions, originating before the Neolithic period, with ceramic objects like the Gravettian culture Venus of Dolní Věstonice figurine discovered in the Czech Republic dating back to 29,000–25,000 BC,

And pottery vessels that were discovered in Jiangxi, China, dating back to 18,000 BC. Early Neolithic and pre-Neolithic pottery artifacts have been found, in Jōmon Japan (10,500 BC),

The Russian Far East (14,000 BC), Sub-Saharan Africa (9,400 BC), South America (9,000s-7,000s BC), and the Middle East (7,000s-6,000s BC). Pottery is made by forming a ceramic (often clay) body into objects of the desired shape and heating them to high temperatures (600-1600 °C) in a bonfire, pit, or kiln and induces reactions that lead to permanent changes including increasing the strength and rigidity of the object.

Much pottery is purely utilitarian, but much can also be regarded as ceramic art. A clay body can be decorated before or after firing. Clay-based pottery can be divided into three main groups: earthenware, stoneware, and porcelain. These require increasingly more specific clay material, and increasingly higher firing temperatures. All three are made in glazed and unglazed varieties, for different purposes. All may also be decorated by various techniques. In many examples, the group a piece belongs to is immediately visually apparent, but this is not always the case.

The Fritware of the Islamic world does not use clay, so technically falls outside these groups. Historic pottery of all these types is often grouped as either “fine” wares, relatively expensive and well-made, and following the aesthetic taste of the culture concerned, or alternatively “coarse”, “popular”, “folk” or “village” wares, mostly undecorated, or simply so, and often less well-made.

Earthenware

- All the earliest forms of pottery were made from clays that were fired at low temperatures, initially in pit fires or in open bonfires. They were hand-formed and undecorated. Earthenware can be fired as low as 600 °C and is normally fired below 1200 °C. Because unglazed biscuit earthenware is porous, it has limited utility for the storage of liquids or as tableware. However, earthenware has had a continuous history from the Neolithic period to today. It can be made from a wide variety of clays, some of which fire to buff, brown or black color, with iron in the constituent minerals resulting in a reddish-brown. Reddish-colored varieties are called terracotta, especially when unglazed or used for sculpture. The development of ceramic glaze made impermeable pottery possible, improving the popularity and practicality of pottery vessels. The addition of decoration has evolved throughout its history.

Project Objective Of Earthen Fresh

Our objective is to make an Earthen pot (made with clay). It will be an evaporative cooler that cools air through the evaporation of water. We are aiming to make the earthen pot with optimized pore fraction/size/distribution to keep the surface wet all the time. With more evaporation, (by making the surface all the time wet), we can keep the temperature at a very low value for a longer duration. Our task will be to bring down the temperature inside the pot so that we can store eatable items.

The porous structure of earthenware allows the inside water to come to the outer surface and continuous evaporation of this water takes away heat from the inside mass and allows the inside temperature to drop thus enabling the earthenware to act as small cold storage.

Hence, if the porosity of the earthenware can be enhanced without affecting or even improvement in the mechanical properties, a better evaporative cooling effect will be attained. In order to achieve the said objective, modification in the market available clay, used for making Ghara (clay pot), has been carried out by adding sawdust and bio charcoal.

Generally, earthenware has a water absorption capacity of 8 to 10% with low mechanical strength. The main aim of our project is to develop a highly porous earthenware having high strength that commercially used pottery.

Project Invention/Proposed Work Plan

Earthenware belongs to ceramics, made up of slightly porous opaque clay, which is fired at moderate temperature in the range of 800-1000°C. Generally, earthenware has a water absorption capacity of 8-12% with low mechanical strength. Continuous evaporation of water from the outer surface of the earthenware takes away heat from the inside mass (water or vegetables) and allows the inside temperature to drop. The porous structure allows the moisture to come to the outer surface and enables the earthenware to act as small cold storage. Hence, if the porosity of the earthenware can be enhanced without affecting or even improvement in the mechanical properties, a better evaporative cooling effect will be attained. The aim of our objective was to develop a highly porous earthenware having high strength than commercially used in pottery. To achieve this objective we had added sawdust/bio charcoal with clay in a certain proportion.

The strength and absorption of water in the porous clay were found to be greater than the market available earthenware.

Along with optimum water absorption and strength, the Sintered Clay also showed high.

Damping properties. Due to being highly porous, the sintered clay has 10 times better damping capacity than Brass and 5 times better than Ceramic Floor Tiles.

Course Of Invention

- Research idea(potential application/basic principles)

- Hypothesis testing and initial proof of concept

- Project plan

- Materials required

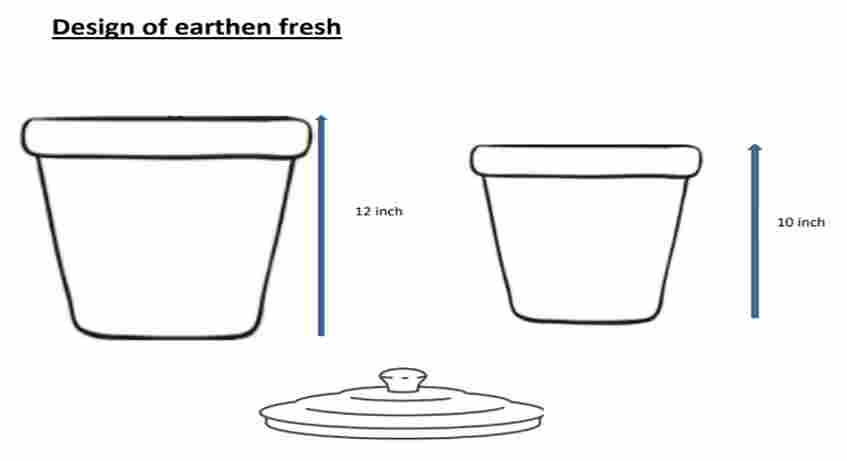

- Designing the pot

- Safety measures

- Validating the prototype

- Clinical trials

- Final testing and evaluation

- Demonstration and commercialization of product

Current Status

The full working model prototype of Earthen Fresh is ready for storage of 5 liters capacity which costs 500/-.

The earthen fresh which has a storage of 25 liters is under the developing stage using walls made with a mixture of clay and sawdust/Biocharcoal.

The present devices in the market are very expensive, thus we are developing a very economical model.

Also, we are aiming to bring down the temperature of the inner pot to 5 -10 °C using different techniques.

Novelty Of Project

Making a highly porous strong sintered clay object by using sawdust and milling.

This has an excellent water-absorbing quality, which can be used for effective evaporative cooling.

The porous sintered clay has excellent damping capacity, particularly for high.

temperature applications where the conventional viscoelastic materials show rapid degradation.

Real-time problem solution for fruit and vegetable vendors.

Solution of storage of food items in rural areas.

Highly economical than other devices present in the market.

Prototype Design

Prototype Cost

FIXED COST | VARIABLE COST (Will be based on Volume of Production) |

1. Electricity + Water Rent (Potters’ wheel) 2. Staff‘s Expenses 3. Advertisement & Marketing | 1. Equipments/ Raw Materials 2. Packaging Cost 3. Transportation Cost 4. Ball Mill |

Future Developments And Commercial Potential

S.no | Companies | Product |

1 | Local village earthen pot makers/vendors | Ghara |

2 | Cottage industries/small scale industries | Earthen storage container |

3 | Rural technological companies | Cold storage |

4 | Nomads/people living in remote areas | Day to day life usage |

Mentions In Media

Article on earthen fresh was published on 17th March 2022 in Dainik Jagran Kanpur newspaper.

Earthen fresh has 100+ pre orders as of now and we will be listing our product shorty on all online websites such as amazon , flipkart etc.

About Inventor

- Anurag Basu is currently pursuing civil engineering (2nd year) from Harcourt Butler technological university, Kanpur.

- He is currently the Associate Head at Tech and innovation department E-cell HBTU.

Harcourt Butler Technical University (HBTU) is a Premier State Technical University in Kanpur, Uttar Pradesh, India. The HBTU was named after Sir Spencer Harcourt Butler, Governor of the United Provinces in British India. Its programs have been conferred autonomous status under the university. It is one of the oldest engineering institutes in the country and holds the ISO 9001:2000 certification. The college recently completed its 100 years of legacy in 2021.