Introduction To Maglev Technology

- By the time we reach middle school we are introduced to the concept of magnetism and its implementations in the real world. Maglev is one such crucial and almost life-altering implementation of magnetism. Basically, the word maglev is derived from magnetic levitation. This is because of the theory behind the technology. It uses two sets of magnets, one to push a compartment into the air or levitate it, and the second to propel it further on the tracks. The main difference between a maglev train and a conventional train apart from the whole levitating and magnet stuff is the lack of friction in the track. Maglevs can be broadly classified into two types, high-speed and low-speed systems. High-speed maglev trains are typically used for intercity travel, reaching top speeds of over four hundred kilometers per hour. Whereas Low-speed maglev trains are generally used for urban city commuting, that is intracity travel often ranging from eighty to two hundred kilometers in speed.

- With maglev technology trains travel along a track laid out with magnets which control the stability and speed of the train amongst other things. Another striking feature of maglev transportation is that no moving parts are required for the levitation and propulsion of the train, however, the carriages themselves require tons of moving parts including retractable wheels, sliding doors, and other supporting systems. All these factors taken into account make maglev trains quieter and smoother than conventional fuel-powered trains or electric-powered trams and have the potential for greater speeds.

History Of Maglev Trains

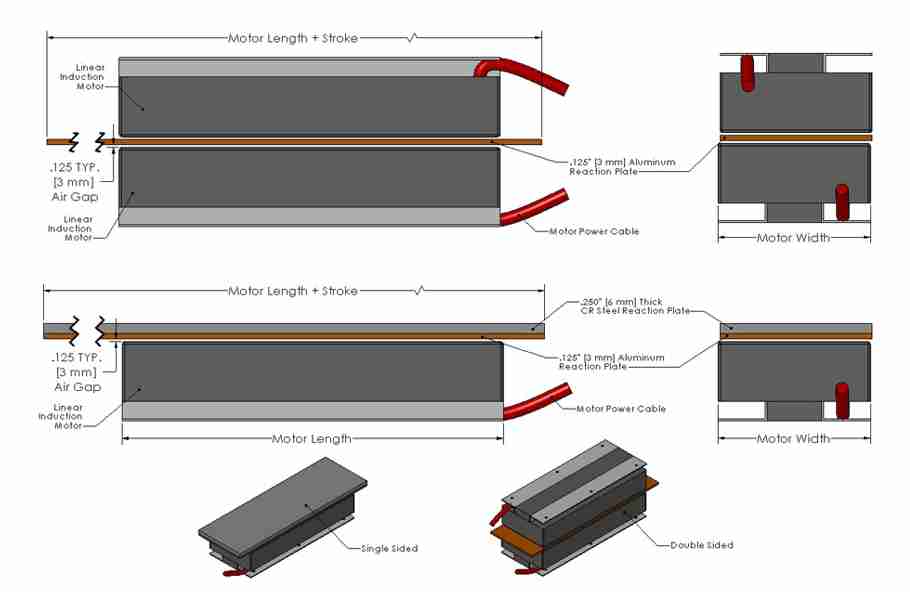

The first ever full-scale model of the linear induction motor, which is the main mechanism for the maglev train was built at Imperial College London, by British professor Eric Laithwaite.

Linear induction motors or LIM do not require physical contact between the vehicle and guideway therefore they became a common fixture on advanced transportation systems during the 1960s and ’70s. All these characteristics of the linear motor made it naturally suited to be used with maglev systems. In the early 1970s, Laithwaite discovered a new arrangement of magnets, a magnetic river, that allowed a single linear motor to produce both, lift and forward thrust which allowed a maglev system to be built with only a single set of magnets. From thereon Laithwaite went on to work in the British Rail Research Division in Darby, developing the “transverse-flux” system alongside a team of several civil engineers. The first commercial maglev people. It was simply called “MAGLEV” and officially opened for the public in 1984 near Birmingham, England.

- All this said the first official relevant patent with regards to Maglev trains was U.S. Patent 714,851, issued to Albert C. Albertson on 2 December 1902, which used magnetic levitation to take a part of the weight off of the wheels of trains while using conventional propulsion.

How Does Maglev Technology Work?

As we have seen, maglev trains do not use wheels. Rather, they are based on magnetic levitation. The trains are levitated a bit above the track through strong electromagnets. The magnets are responsible for moving the train as they are responsible for creating thrust.

Maglev trains are known to have superior controls with respect to conventional trains. In addition, their deceleration doesn’t really depend on the track friction. As this train functions on an interesting concept. Currently, three operational commercial maglev systems are present in the world, located in South Korea, China, and Japan. This discussed mechanism is achieved by three essential parts: levitation, propulsion, and guidance.

Levitation

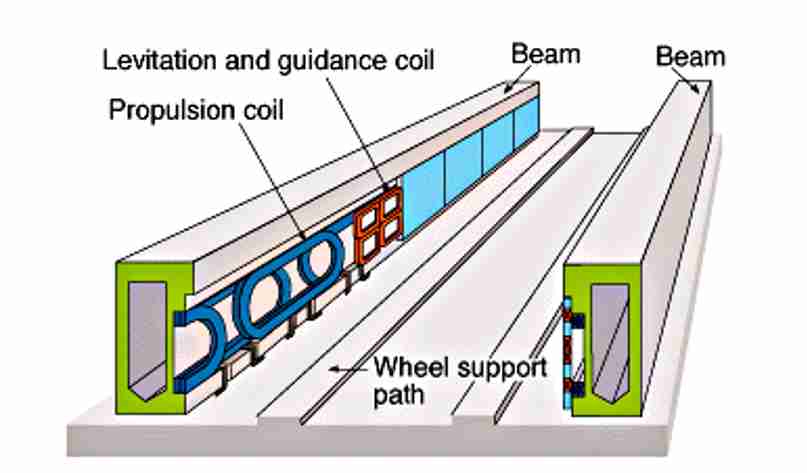

- Levitating refers to the phenomenon that keeps the train suspended above the track. Under the levitating technology, there are two types known as electrodynamic suspension and electromagnetic suspension.

1. Electrodynamic Suspension:-

This suspension technique creates a strong magnetic field using superconducting or permanent magnets. The strong magnets levitate the train by producing attractive and repulsive force.

A continuously varying magnetic field is generated through the alternating current of the propulsion coils on the guideway. The rhythm of the alternating coil is continuously changed through the poles of the magnet on the guideway. The changing magnetic field is responsible for guiding the train and moving it forward. The speed of maglev trains can be controlled by changing and altering the current.

2. Electromagnetic Suspension:-

Another levitating way is electromagnetic suspension. This is where a magnetic field is exerted using magnets. In this case, the conductors under the guideway attract the train’s levitation magnets. The train is levitated even if the speed is low.

Also, passengers traveling inside the train with a pacemaker or magnetic storage like a hard disk are safe. The magnetic intensity inside the train is minimal and is of no risk. EMS maglev trains come with an emergency power battery supply that keeps the train running in the event of power failure too.

Propulsion: Maglev trains use an electric motor linear that offers propulsion, a force that keeps the train moving forward. Torque and spin, and axle are created through normal electric rotary motors. Here, a rotating piece, the rotor, is surrounded by a stationary piece, the stator.

A rotating magnetic field is generated using a stator. The magnetic field helps the rotor to spin by inducing a rotational force. The rotor is placed on the stator.

Electric linear motion can produce motion in a straight line. It is possible because a stator generates a field instead of a rotating magnetic field that travels down its length. Similarly, the rotor experiences a linear force.

It’s important to remember that the rotor produces liner force only when it’s above the stator. When it reaches the end, it stops.

Guidance: Guidance is a concept that is responsible for keeping the train in the center. It is achieved using repulsive magnetic forces. Two electromagnetic rails facing either side of the guideway are kept on the train in the Trans Rapid.

Here, the levitating rails are connected. This connection induces a restoring force that helps push the train back to the center if it moves close to one side.

Tracks: The term “maglev” refers not only to the vehicles but to the railway system as well, specifically designed for magnetic levitation and propulsion. All operational implementations of maglev technology make minimal use of wheeled train technology and are not compatible with conventional rail tracks. Because they cannot share existing infrastructure, maglev systems must be designed as stand-alone systems. The SPM maglev system is inter-operable with steel rail tracks and would permit maglev vehicles and conventional trains to operate on the same tracks. MAN in Germany also designed a maglev system that worked with conventional rails, but it was never fully developed.

Stability: Earnshaw’s theorem shows that no combination of static magnets can be in a stable equilibrium. Therefore, a dynamic (time-varying) magnetic field is required to achieve stabilization. EMS systems rely on active electronic stabilization that constantly measures the bearing distance and adjusts the electromagnet current accordingly. EDS systems rely on changing magnetic fields to create currents, which can give passive stability.

Because maglev vehicles essentially fly, stabilization of pitch, roll, and yaw is required. In addition to the rotation, surge (forward and backward motions), sway (sideways motion), or heave (up and down motions) can be problematic.

Superconducting magnets on a train above a track made out of a permanent magnet lock the train into its lateral position. It can move linearly along the track, but not off the track. This is due to the Meissner effect and flux pinning.

Proposed Technology Enhancements For Maglev

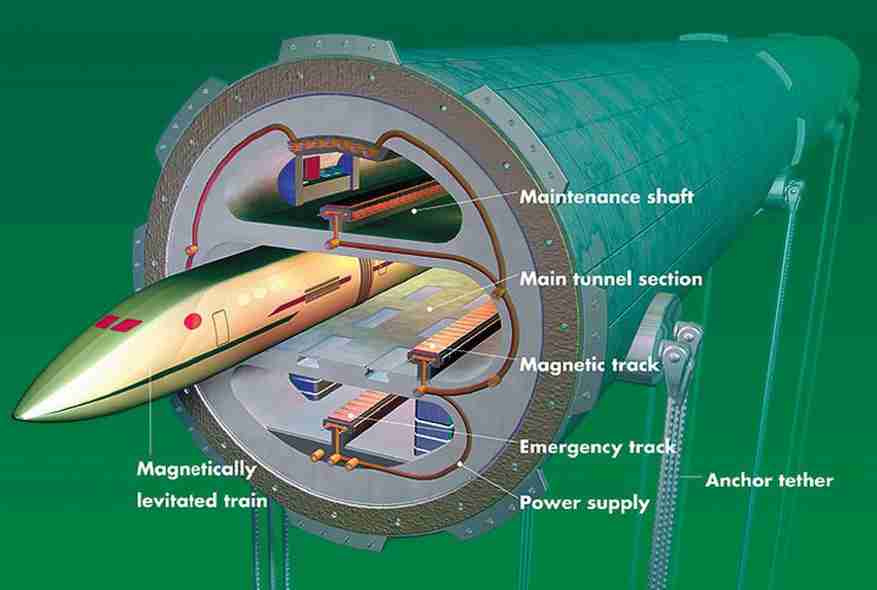

1. Evacuated tubes: Some systems (notably the Swiss metro system) have proposed the use of vactrains (maglev train technology used in evacuated or vacuum tubes), which removes air drag. This has the potential to increase speed and efficiency greatly, as most of the energy for conventional maglev trains is lost to aerodynamic drag.

One potential risk for passengers of trains operating in evacuated tubes is that they could be exposed to the risk of cabin depressurization unless tunnel safety monitoring systems can repressurize the tube in the event of a train malfunction or accident. Although trains are likely to operate at or near the Earth’s surface, emergency restoration of ambient pressure should be straightforward. The RAND Corporation has depicted that a vacuum tube train could, in theory, cross the Atlantic or the USA in around 21 minutes.

2. Rail-maglev hybrid: The Polish start-up Nevomo (previously Hyper Poland) is developing a system for modifying existing railway tracks into a maglev system, on which conventional wheel-rail trains, as well maglev vehicles can travel. Vehicles on this so-called ‘magrail’ system will be able to reach speeds of up to 300 kilometers per hour at significantly lower infrastructure costs than stand-alone maglev lines. Similar to proposed Vactrain systems, magrail is designed to allow a later-stage upgrade with a vacuum cover which will enable vehicles to reach speeds of up to 600 km/h due to reduced air pressure, making the system similar to a hyperloop, but without the necessity for dedicated infrastructure corridors.

Energy Use In Maglev Trains

The energy expenditure and savings in maglev trains are pretty weird, to be honest. Most of the energy is used by maglev trains for acceleration. However, energy is regained when the train slows down via regenerative braking. Most of the energy is needed to overcome air drags. Some energy is used for air conditioning, heating, lighting, and other miscellaneous tasks.

At lower speeds the percentage of power used for levitation is significant. Consuming up to 15% more power than a subway or light rail service. For short distances, the energy used for acceleration is considerable too. From the standpoint of physics, the force used to overcome air drag increases with the square of the velocity and hence dominates at high speed. The energy needed per unit distance is proportional to the square of the velocity and inversely proportional to the time. However, it’s important to note that power increases by the cube of the velocity.

A fascinating thing is that aircraft take advantage of lower air pressure and lower temperatures by cruising at altitude to reduce energy consumption but unlike trains need to carry fuel on board owing to these, suggestions of conveying maglev vehicles through partially evacuated tubes have emerged which would make these trains considerably efficient and faster.

The Two Types Of Maglev Trains

High-speed systems:-

The Shanghai maglev demonstration line is probably the best example of the high-speed maglev transit system. In 2004 the total manufacturing cost of this particular maglev train system was around one point two billion us dollars. Although ridership is not the primary focus of the demonstration line due to its position being in the eastern outskirts of Shanghai, if the track were to be extended to cover southern Shanghai, ridership was believed to be substantial enough to cover operational and maintenance costs alongside generating a significant and stable net revenue.

Another example of this would be the Chuo Shinkansen maglev, proposed in Japan (which is one of the largest implementors of maglev trains in the world) the system was estimated to cost approximately eighty-two billion us dollars to build, with a route requiring long tunnels.

Low-Speed Systems:-

One of the prime examples of Low-speed maglev train systems is the Japanese Linimo HSST. The approximate cost of building this particular system was a hundred million us dollars per kilometer of track. The prime advantage of these types of systems is that they offer improved operations and lower maintenance costs over other transit systems. These low-speed maglev trains provide extreme levels of operational reliability, introduce little to no noise and generate zero air pollution in urban settings.

Advantages And Disadvantages Of Maglev Trains

Advantages:-

The foremost advantage of maglev trains is that they do not have a moving corridor as conventional trains do, and thus, the wear and tear and gash of parts is minimum. This reduces the conservation cost by a significant extent.

More importantly, there’s no physical contact between the train and track, so there’s no rolling resistance. While electromagnetic drag and air disunion do live, that doesn’t hamper their capability to timepiece a speed in excess of 200 mph.

The absence of a bus also comes as a boon, as you don’t have to deal with the blaring noise that’s likely to come with them.

Maglevs also boast of being terrain friendly, as they don’t resort to internal combustion machines.

These trains are rainfall evidence, which means rain, snow, or severe cold wave don’t really hinder their performance.

Experts are of the opinion that these trains are a lot safe than their conventional counterparts as they’re equipped with state-of-the-art safety systems, which can keep effects in control indeed when the train is cruising at a high speed.

Disadvantages:-

Extremely high cost of initial setup.

- While the fast conventional trains that have been introduced, work fine on tracks which were meant for slow trains, maglev trains bear an each-new set up right from scratch.

Top 13 Interesting Facts About Maglev Trains

The driverless bullet train is capable of clocking a speed of 500 kmph while running 10 cm above the ground.

The train Chuo Shinkansen, in its first phase, will connect three of the largest cities of Japan, covering 286 km distance between Tokyo and Nagoya in 40 minutes from its current 86 minutes.

The Japanese maglev bullet train, Shinkansen, sports a sterling record of zero fatalities over its 50 years of operations.

Scientists at Southwest Jiaotong University in China have built a prototype testing platform for a near-vacuum high-speed maglev train that is theoretically capable of reaching speeds up to 2900 km/h or about 1,800 mph.

Berlin was the first world capital to have a Maglev train open to public traffic.

By 2025 it is estimated that Maglev trains will be capable of reaching speeds of 900 km per hour.

By 2020 it is estimated that Maglev trains will be capable of reaching speeds of 800 km per hour.

Researchers are looking into a “Vactrain” system where they could send a maglev train through a vacuum tube at 2,500 mph. Furthermore, they are looking into drilling the tubes through Antarctica since ice is less dense than rock.

The Maglev covers a distance of 30.5 kilometers in 8 minutes.

They are less expensive to operate and maintain because the absence of rolling friction means that parts do not wear out quickly.

The design of the maglev railway is such that derailment is almost impossible.

Owing to the stability, Maglev railcars can be built wider than conventional railcars, offering more options for using the interior space and making them more comfortable to ride in.

As there is no friction, the train produces almost no sound making the ride smoother for the passengers.